The study of tire and road wear particles has accelerated in recent years, with global research and testing paving the way for possible future legislation and design solutions. TTI looks at current projects and strategies that address tire wear pollution.

The heightened awareness of microplastic pollution and the more widespread adoption of zero-tailpipe-emission electric vehicles has seen tires come under ever-closer scrutiny for their potentially harmful emissions – the tire and road wear particles (TRWP) that are produced by the necessary friction between tires and the road surface. A 2010 Kreider et al study estimated that TRWP comprises around 50% tire tread and 50% road pavement material. With a density of ~1.8g/cm3, TRWP material is expected to sink in water, and further analysis suggests it may pick up additional elements from road surfaces, including fuel, brake dust and other sediments.

Some industry studies have shown that TRWP affects certain species. However, other research has indicated that it is unlikely to pose significant risks to human health or the environment. So while the true TRWP picture is still emerging, trade organizations USTMA (US Tire Manufacturers Association), ETRMA (European Tyre and Rubber Manufacturers’ Association) and the Tire Industry Project (TIP) – operated by the World Business Council for Sustainable Development (WBCSD) – remain firmly committed to understanding the potential impacts of TRWP.

“As with all research, consistent and rigorous methodologies are critical to enhancing the validity and repeatability of TRWP research,” says Dr Larisa Kryachkova, who is executive director of TIP and a member of the WBCSD Extended Leadership Group. Bringing together the 10 leading tire companies, TIP-sponsored research has, over the past two decades, developed a marker to identify tire wear in the environment, identified how TRWP are dispersed into the environment, assessed exposure to TRWP in freshwater environments and conducted human health and environmental risk assessments.

“As with all research, consistent and rigorous methodologies are critical to enhancing the validity and repeatability of TRWP research,” says Dr Larisa Kryachkova, who is executive director of TIP and a member of the WBCSD Extended Leadership Group. Bringing together the 10 leading tire companies, TIP-sponsored research has, over the past two decades, developed a marker to identify tire wear in the environment, identified how TRWP are dispersed into the environment, assessed exposure to TRWP in freshwater environments and conducted human health and environmental risk assessments.

“Additional research includes the modeling of TRWP fate and transport in soil, air, rivers and oceans; environmental sampling to validate modeling work; studying the degradation of TRWP in the environment; and investigating the potential impacts of long-term exposure of organisms to TRWP,” Kryachkova continues. TIP expects six new studies to be published during the second half of 2023, adding to the 19 published research papers it has supported since 2009.

Spanish testing facility Applus Idiada recently participated in a study funded by the European Commission to develop a standard testing protocol for measuring tire abrasion, as no such procedure currently exists. The 15-month project began in 2021 and focused on accelerated test cycles. “We used a proving ground test control environment because it is more controlled and stable than an open road,” says Ricard Anadón, Applus Idiada senior product manager for tire and wheel homologation and certification. Compared with an open-road test program, Anadón and his colleagues’ study was six times shorter.

“A certain amount of test distance is needed to see some tire degradation or mass reduction. We tried to accelerate tire wear with an aim to reduce the test length to shorten the full distance, but there are issues,” he explains. These include correlations between public roads and the proving ground, the need for additional tire tests and the available budget.

Standard abrasion test

ETRMA and USTMA support the development of a standard test to measure tire abrasion, to standardize understanding of the wear rates of different tires. The tire industry is an active contributor, having initiated development of test methods at the UN Economic Commission for Europe (UNECE) and International Organization for Standardization (ISO).

“In addition, a Task Force on Tire Abrasion (TFTA) under the UNECE has been commissioned to recommend abrasion limits for tires to limit the emission of microplastics into the environment and to develop a UN regulation for the type approval of tires with respect to their abrasion,” says Adam McCarthy, ETRMA secretary-general. This process is expected to validate test methods by January 2024. “A Tire Abrasion Working Group led by ETRTO (European Tyre and Rim Technical Organisation) and JATMA (Japan Automobile Tyre Manufacturers Association) within the ISO is developing on-vehicle and indoor drum test methods that are expected to validate test methods by 2024,” he continues.

Anadón and his colleagues are part of the UNECE TFTA Working Party on Noise and Tyres (Groupe Rapporteur Bruit et Pneumatiques – GRBP). “Participants come from the industry, authorities, independent technical services and other fields,” he says, noting new regulations usually take around five years to come into force.

ETRMA and USTMA have also sponsored a state of knowledge study, or literature review, to identify known mitigation solutions for TRWP. Conducted by the Fraunhofer Institute for Environmental, Safety, and Energy Technology (UMSICHT), Carnegie Mellon University and Karlsruhe Institute of Technology (KIT), this is expected to be published within the next few months. It should identify more than 50 mitigation measures, including those that can reduce TRWP. These include improvement and maintenance of roads and road surfaces, and measures that can capture TRWP, such as street sweeping and wastewater treatment.

Previously involved in the 2017-2021 RAU – Reifenabrieb in der Umwelt/Reducing the Environmental Impact of Microplastics from Car Tires – project, Daniel Venghaus MSc, a research associate in the Department of Urban Water Management at the Technical University of Berlin, has been studying roadside microplastic filtration systems.

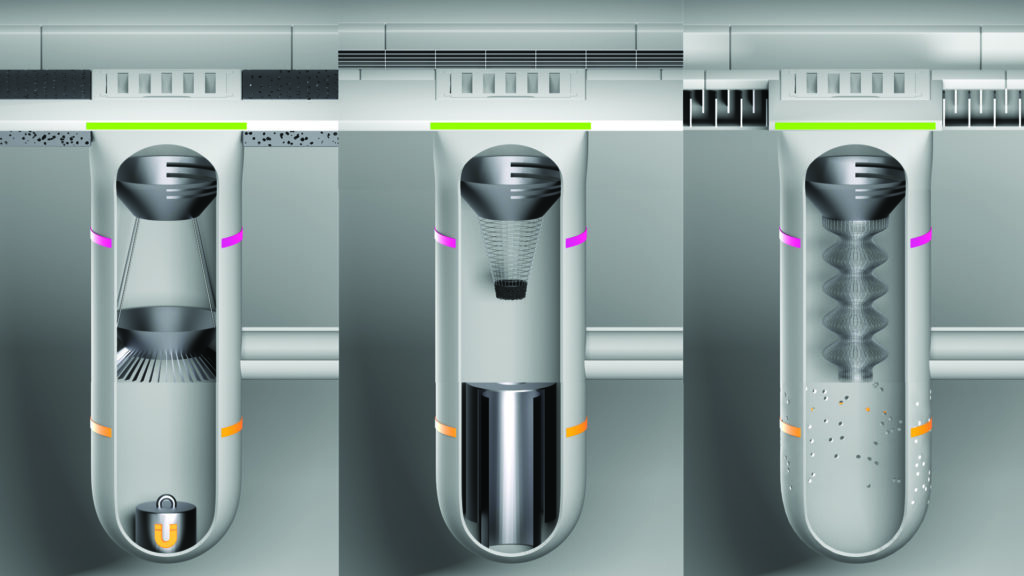

“Completed with the Audi Environmental Foundation, the field and lab test Urbanfilter project looked at how roadside filters can prevent TRWP from being washed into water bodies with rainwater,” he says. The funnel-type filters feature a stainless-steel mesh skirt to collect debris and to direct water down into the slug area of the road gully. At the bottom of the skirt, a magnet module binds fine and ultrafine particles. Partially integrated into the road, porous asphalt traps particles before they wash into the storm drain, so the filters trap particles as close as possible to the locations where they are generated.

As the filters had to deal with all road debris, nine modules were developed to separate the microplastics and the solid particles.

“These can be divided into three zones – road, sewer and drain – and up to three modules can be combined at any location for the best result,” reports Venghaus. The porous asphalt at street level can help keep the very small refined matter particles – including TRWP – from entering the filter, and when combined with street cleaning services before a significant rain event, the washing away of TRWP particles into road gullies can be avoided. Before field evaluations, the Urbanfilter system passed laboratory tests of different size fractions from <63µm up to 2,000μm, in light to medium rainfall conditions. Real-life ‘hot spots’ were then identified for an analytical field test sampling strategy. For tire wear, populated areas with curves, intersections and traffic signals were identified, as these could have pollutant levels three to eight times higher than straight roads.

Active role

Tire makers can obviously help to address TRWP, too, and are already playing an active role, according to McCarthy.

“Our members are committed to advancing sustainable manufacturing practices as detailed in USTMA’s sustainability reporting, and have made commitments to advance the UN’s sustainable development goals,” he explains.

“Manufacturers do need to understand how the particles are generated, how big they are and what their density is,” Venghaus adds.

Tire design presents other routes to potential solutions, but needs delicate consideration.

“It is important to understand that the composition and nature of the chemicals present in tires impart critical safety and performance functions. Their exact composition cannot be modified without great care,” says Anne Forristall Luke, USTMA president and CEO. The organization’s members – including Bridgestone, Goodyear, Michelin, Nokian and Pirelli – are committed to advancing design solutions through the use of recycled and renewable material.

With so many factors affecting wear and TRWP generation – design, vehicle characteristics (including weight, load distribution, driving wheel location and suspension types), road surface (material, runoff design, roughness), weather, road topology and driving behavior – there is no one-size-fits-all solution. Furthermore, McCarthy believes there is a need for additional research to understand the role EVs will play in the generation of TRWP.

“The state of knowledge report on TRWP mitigation found increased vehicle weight and torque from electric vehicles are expected to increase tire wear,” he says. “However, the role regenerative braking might play in decreasing tire wear needs to be better understood.”

“The state of knowledge report on TRWP mitigation found increased vehicle weight and torque from electric vehicles are expected to increase tire wear,” he says. “However, the role regenerative braking might play in decreasing tire wear needs to be better understood.”

All future solutions – legislative or otherwise – need a collaborative approach, and due to the complex factors involved, it’s hard to pinpoint timetables to better outcomes.

“It’s difficult to put a specific timeframe on when better solutions to TRWP will be found, because there are so many different – and often competing – factors affecting the development and implementation of effective solutions,” says Forristall Luke.

“TRWP can be difficult to study because environmental conditions where they are found vary greatly,” adds Kryachkova. “Peer-reviewed scientific research has shown the outcomes of studies for TRWP depend on test material used, species tested, exposure concentrations and end points evaluated.”

Collaboration on those solutions is key. “Fronted by TIP’s ongoing research, the global tire industry is engaged in and supporting a holistic approach, which we believe – given the complexity and multistakeholder nature of the issue – is a necessary approach,” states Kryachkova.

“A center for competence could make the way forward far more open and clear, as it could optimize technologies and facilitate interdepartmental discussions,” believes Venghaus. “Here, industry stakeholders could work together on pilot projects. At the moment, there could be someone working on another project and no one else would know about it. Open-source approaches are an important step.”

Sustainable road surfaces

The composition of the road is as important as that of the tire

Alongside tires and tire material innovations, USTMA’s Anne Forristall Luke confirms that more sustainable road surfaces such as rubber modified asphalt (RMA) can play an important role in reducing TRWP generation.

“RMA is a mixture of recycled ground tire rubber and asphalt, which has proven economic, environmental and performance benefits. A 2006 study by the University of Arizona found RMA reduced tire wear by roughly 50% compared with roads paved with concrete,” she reports. “Further, recent research in Oregon has found the use of porous pavement reduces TRWP and 6PPD-Quinone – a previously unknown transformation product of tire ingredient 6PPD, used to help resist degradation and cracking – by roughly 90%,” she says, adding that the pavement surface plays a critical role in the production of TRWP. However, additional research is needed to understand which types optimize TRWP generation.

“Road surface has an impact on tire abrasion, in particular the microtexture, but this is something that helps control the tire. High grip levels give high tire abrasion,” says Applus Idiada’s Ricard Anadón. “Grip levels cannot be reduced through braking, acceleration or cornering forces, as grip is needed.”

Creation of a surface test would not be easy, he believes, as different countries use different surfaces.

For more on TRWP, please click here.