Gemma Hatton meets a collective of design and engineering students aiming to tackle the issue of tire road wear particles with the latest in scientific innovation

While the fight to reduce vehicle tailpipe emissions continues, there is another type of emission that is polluting our environment – one that is far less often discussed, but that requires immediate attention: the particles from tire wear.

“Every time we accelerate, brake or corner, tire dust enters our waterways, our food chain and the air we breathe,” says Siobhan Anderson, co-founder of The Tyre Collective. “It’s estimated that we eat about a credit card’s worth of plastic every week. In fact, microplastics are accumulating on the ocean floor so densely that scientists say that this will be preserved as an identifiable time period in our bedrock.”

So, reducing and then eliminating tailpipe emissions won’t automatically mean the end of future vehicle pollution. Tire wear is the second-largest microplastic pollutant in our environment and a major contributor to air particulate emissions (PM2.5 and PM10) from road transport. The average car tire loses a total of 4kg of plastic throughout its lifetime due to wear. With 1.4 billion vehicles in the world, the severity of the problem is obvious.

As adoption of EVs continues, the added weight of components such as batteries, motors and inverters will increase tire wear. A recent UK report to the UN Convention estimates that emissions due to tire and road surface wear could increase by as much as 1.7kt over the next decade. To try to solve this issue, the UK has issued its first call to action.

Catch in the act

Of course, the obvious solution is to try to develop tires that have reduced wear rates or are made from environmentally friendly materials.

“If that’s possible, then it’s a long way off – the technology and the infrastructure just aren’t there yet,” explains Hugo Richardson, another co-founder of The Tyre Collective. “In the meantime, the current nature of tires means that there will always be a level of wear, and that rubber will end up somewhere. So, we’ve developed a device that acts as a sort of stopgap, creating a circular economy around tires until this ultimate ‘green tire’ exists.”

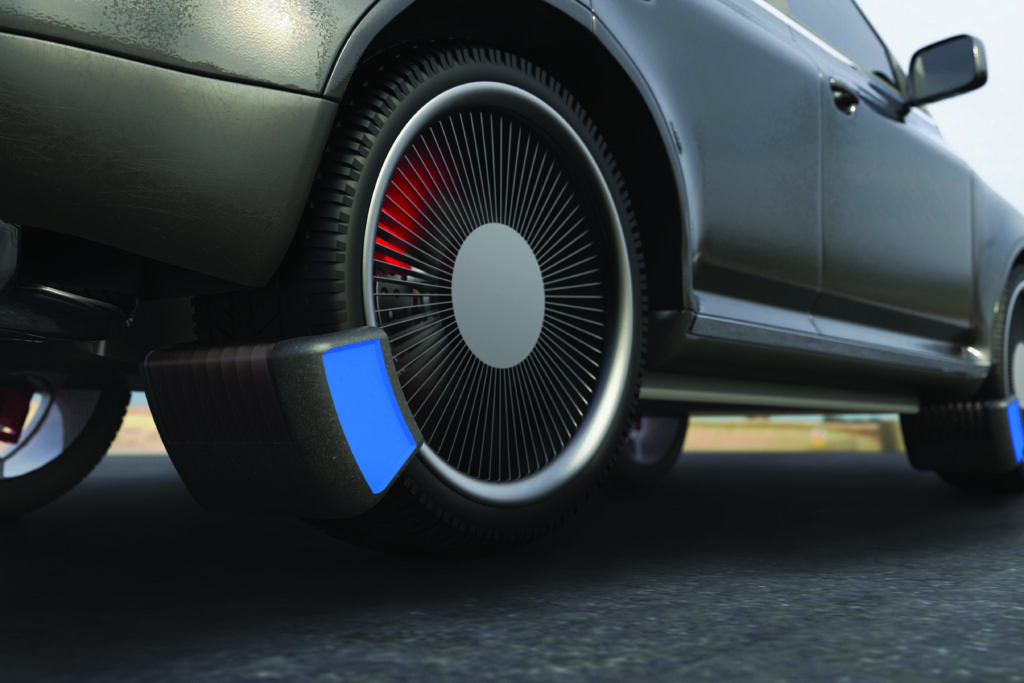

The Tyre Collective is a UK tech startup founded by a group of design and engineering students from Imperial College London and the Royal College of Art. Their device uses a single array of electrostatic plates that captures tire dust from the turbulent airflows behind the spinning tire. The latest design captures 60% of all airborne particulates on test rigs and was the UK winner of the 2020 National James Dyson Award.

“We decided quite early on that the best place to intervene is on the vehicle itself,” explains Richardson. “Once tire particles are dispersed, they are practically impossible to capture, so if you start putting devices within the built environment then you’ll only capture a fraction of what’s actually being produced.”

Throughout the initial design phase, Richardson and his colleagues experimented with different filtration and suction systems. However, the aim was to create a device that had a negligible effect on the vehicle’s mileage, so it had to be lightweight and consume minimal energy.

“We didn’t want to replace one type of pollution with another, by affecting the weight or available energy so that the vehicle would travel fewer miles per gallon of fuel or kilowatt of energy. That’s what prompted us to use the airflow as a passive form of propulsion,” explains Richardson. “We then iterated through various experiments. One of our early successes was rubbing a balloon against a sweater and watching the shaved tire particles jump up and down. We discovered that the rubber particles coming off tires become charged due to friction with the road. This meant that we could use an electrostatic precipitator to capture these particles, separating them from the airflow.”

To capture the tire particles before they are dispersed into the atmosphere, the device needed to be as close to the contact patch as possible. However, practical requirements such as ground clearance meant that the device had to sit further back. To still entrain as much dust-filled air as possible into the system, the students ran complex CFD simulations to try to understand the behavior of the airflow behind the tire.

“We then input that CFD model into a MATLAB simulation where we were able to model the behavior of the electrostatic and gravitational forces along with the airflow,” reveals Richardson. “This allowed us to generate particles at the tire’s contact patch and then step through the simulation to see how these particles behaved within the airflow. So, we could quickly and easily change parameters, such as the size of the plates or the spacing between them, and then run a kind of Taguchi method to see which parameters had the greatest effect on the particle capture efficiency.”

Complementing these analytical models, The Tyre Collective team also conducted a variety of physical tests using an initial lab prototype as well as full-scale tire dynamometers. This helped to not only validate the models but also test the device’s durability within the chaotic environment of the tire’s wake. “It is a complex area to intervene in, so we’ve also had to run FEA simulations to ensure the structural integrity of the device,” says Richardson.

The device is attached to the steering knuckle via an attachment arm, which enables it to turn with the wheel and move in unison with the suspension. However, this means the device is subjected to intense accelerations that it needs to be able to withstand.

“Currently we’re still working on bringing the different subsystems together within one device and then we’ll work on optimizing it to be lighter, cheaper and easier to manufacture,” explains Richardson. “Some of our prototypes have used 100% recycled 3D-printed nylon filament, because it’s important for us to minimize the environmental effect of this product throughout its lifecycle.”

Waste not

The first on-vehicle tests were completed in Sweden this summer, and the samples of captured tire particles were undergoing analysis in the lab at the time of writing. It’s not just the amount of tire particles captured that is important, but also the quality of the rubber that can then be extracted.

Current tire recycling processes involve cryogenically freezing rubber with liquid nitrogen and then grinding it up. This changes the chemical composition of the rubber. The team at The Tyre Collective hopes that by grinding the rubber particles at room temperature or slightly higher, they can upcycle rubber into products that have equal or more value.

“We knew early on that, in parallel with the development of our technology, a system would need to be in place for repurposing this captured waste material,” says Anderson. “The captured tire particles are stored in a cartridge within the device, which can then be removed and emptied during servicing. In our lab we can then refine the tire particles through density separation and use solvents to break down the natural compounds. The resulting particles can then be reused in a variety of applications, such as in the outer soles of shoes, dyes and even in the retread of tires. This not only adds value to this waste stream but also creates a closed-loop system.”

The aim is to bring the device to market as part of a pilot trial in 2022, with the students targeting fleet vehicles first. Although the device can be adapted to different vehicle types, the greater likelihood of uniformity within delivery fleets makes it an ideal starting place. Furthermore, the process of emptying the cartridge can be easily integrated into routine maintenance schedules.

Once the device and the necessary refining processes have matured, the potential of this particulate-capturing technology could be huge.

“In the future we want to widen our CFD analysis to look at the airflows of other vehicles,” concludes Richardson. “We want to develop our device to capture tire particles from other vehicles as well, cleaning up debris as it is used. So not only will it help the vehicle it is attached to achieve zero emissions, but it will reduce the emissions of other vehicles too, having a truly positive impact on our environment.”