Alan Bennetts, owner at Bay Systems, investigates tire failure mechanisms using exterior temperature sensing.

Durability testing usually represents a large majority of the work undertaken by the testing department. Making a tire that meets or exceeds the required standard, with as few iterations as possible, is the objective.

A tire running at high speed and full load may transition from, what appears to look and sound like normal running, to failure in just a few seconds. Detection of the impending failure, in time for the tire to be retrieved in one piece from the test rig, is usually achieved by anarrangement of sensors that detect a change in the size of the tire.

These techniques work well but do not detect all failures and typically do not provide any useful data that can help diagnose the mechanisms that led up to the failure. The underlying cause of all failures is excessive heating of the tire leading to component separation and catastrophic failure of the tire.

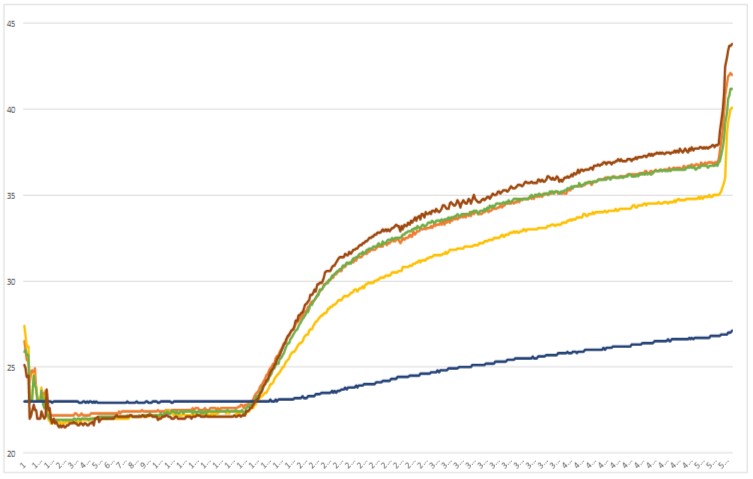

During testing when tires are run at loads and speeds that keep temperatures below 100°C, it is possible to gather noise, vibration and temperature data from sensors mounted inside the tire cavity. The temperature sensing technology developed by Bay Systems for the Tire Cavity Thermometer (TCT) would, in principal, be ideal as a failure detector but for temperatures routinely exceeding 150°C in durability testing. Temperatures over 100°C are problematic for all electronic components and batteries, making the use of internal sensors impossible or very expensive. The alternative selected for this project was exterior temperature sensing making use of the technology developed for the TCT. The Tire Damage Alarm (TDA) delivers the accuracy and resolution required to reliably trap impending failures cost effectively. An example of TDA data for a tire running at 100km/h and then quickly accelerating to 200km/h is shown in Figure 1 (above).

The alternative selected for this project was exterior temperature sensing making use of the technology developed for the TCT. The Tire Damage Alarm (TDA) delivers the accuracy and resolution required to reliably trap impending failures cost effectively. An example of TDA data for a tire running at 100km/h and then quickly accelerating to 200km/h is shown in Figure 1 (above).

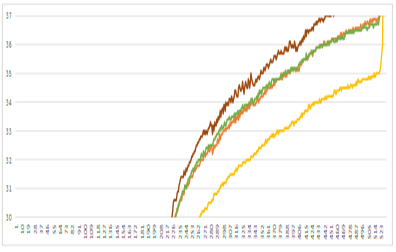

Careful inspection of the traces in Figure 1 will reveal some barely noticeable variations in the ‘outer shoulder’ trace (brown) that a casual glance would miss. The area of the graph containing the variations is expanded and shows an interesting, ‘saw tooth’ structure hidden within what initially appeared to be a smooth curve (Figure 2, below).

The possibility of electrical noise being picked up preferentially by the outer shoulder channel is unlikely. The data was acquired using four identical sensors connected to the same power and data bus. Each sensor was shielded in an earthed metal enclosure, as was the micro-computer that controlled sampling and radio transmission to the tablet PC. The acquisition rate was one sample every 10 seconds. Each sampled temperature was therefore separated by approximately 100+ wheel rotations, sufficient time for a genuine temperature change inside the tire to propagate to the surface.

The question still remains as to whether this saw tooth signal is genuine. The plan is to repeat the measurement on a number of tires both to confirm that the effect exists and to see if it is present on other tires. If these tests prove that the data presented here is genuine then explanations for the effect can be considered.

The question still remains as to whether this saw tooth signal is genuine. The plan is to repeat the measurement on a number of tires both to confirm that the effect exists and to see if it is present on other tires. If these tests prove that the data presented here is genuine then explanations for the effect can be considered.

A possible and attractive explanation would be that a change is taking place within the tire structure, possibly triggered by repeated strain cycles at a certain temperature. This theory is at least logical as the outer shoulder is where maximum deformation happens, thereby explaining why the effect is most prominent at the outer shoulder location.

The amplitude of the ‘saw tooth’ signature might also correlate with the level of hysteretic energy dissipation occurring in each region of the tire. The minimization of this hysteresis might then prove a reliable guide to which structural modifications would lead to a tire with a reduced rolling resistance.