The KraussMaffei Group is among the world’s leading suppliers of machinery and systems for producing and processing plastics and rubber.

Our brand has been synonymous with cutting-edge technology for over 180 years. Our range of services covers all areas of injection molding machinery, extrusion technology and reaction process machinery. This gives KraussMaffei a unique selling point in the industry. With the high innovative power of our standardized and individual products, processes, digital and service solutions, we can guarantee customers sustained added value over the entire value-adding chain. Our range of products and services allow us to serve customers in many sectors including the automotive, packaging, and medical and construction industries, as well as manufacturers of electrical and electronic products and household appliances. KraussMaffei employs around 5,000 people all over the world. With more than 30 subsidiaries and over 10 production plants, as well as about 570 commercial and service partners, we are represented internationally close to our customers. KraussMaffei has been headquartered in Munich since 1838.

As an expert partner for the tyre manufacturing industry, KraussMaffei delivers complete leading-edge systems for the production of tyre components. Our goal is to offer the made-to-measure solutions you need to succeed in today’s fast moving competition.

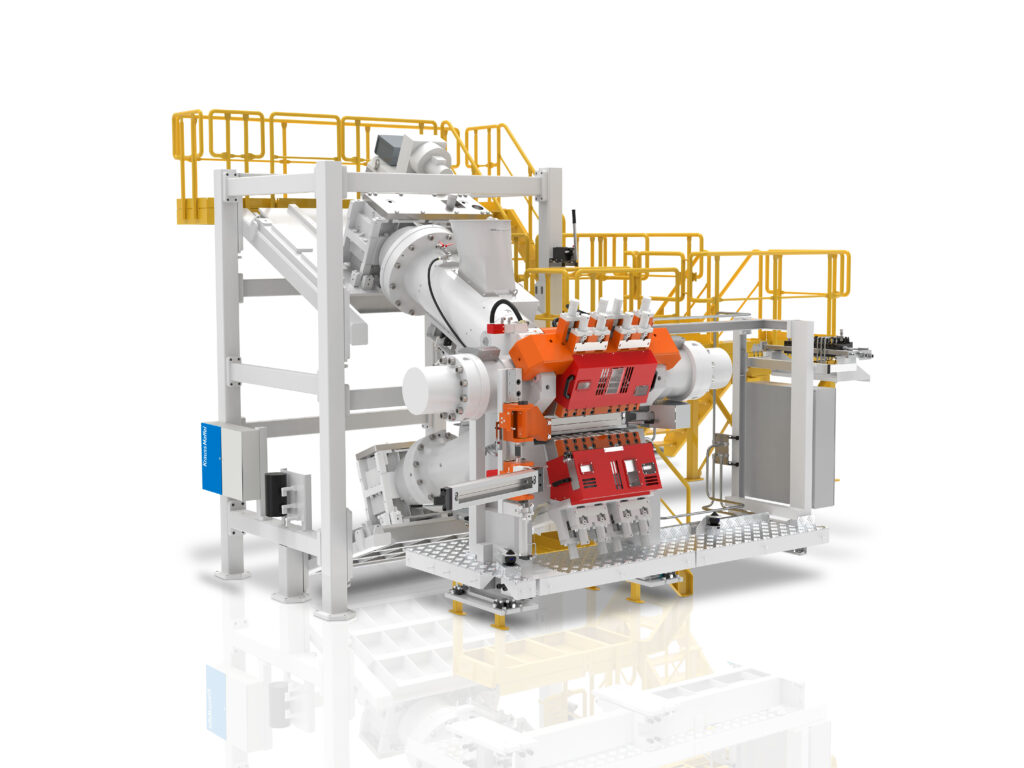

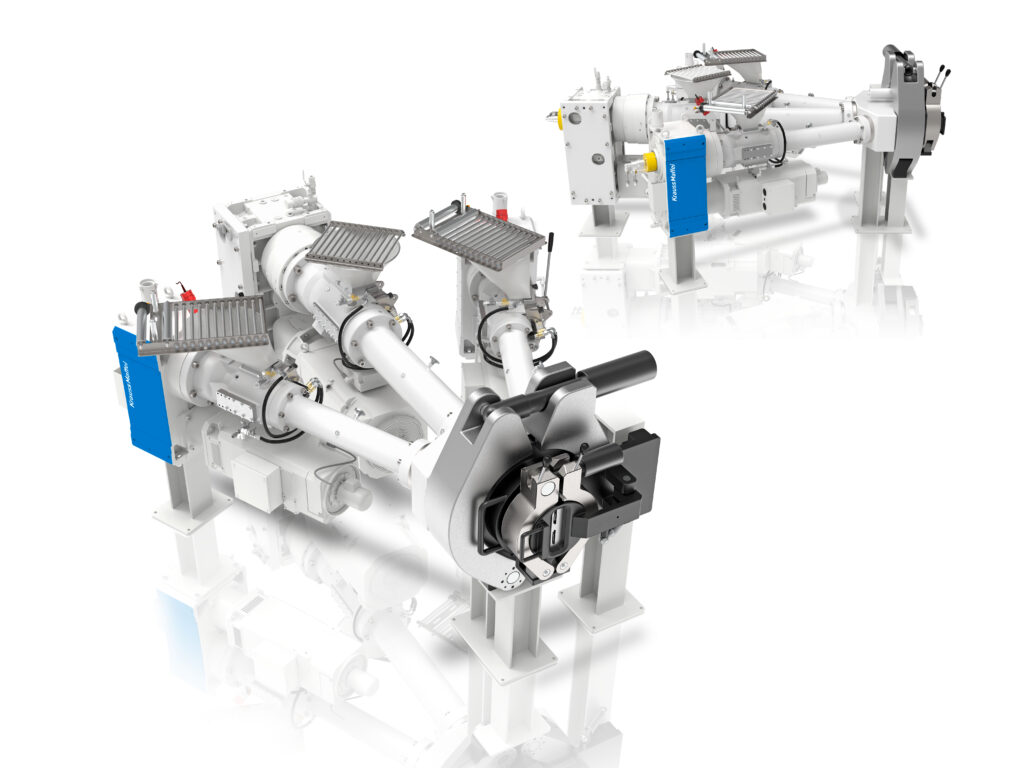

In our product portfolio you find extrusion lines with the highest throughput-rates in the market. Precision and cost-effectiveness Roller-Head systems for rubber sheets and strips, Strainer solutions for a high compound quality, Multiplex extrusion aggregates with up to 7 extruders, unique machinery as C-Check device, CompoundRework System, SEALANT module or Extruder for APEX, BEAD and Cap Strip.

Proven engineering power, unrivalled technological expertise, numerous patented developments and active participation in the production processes of the tyre manufacturers testify to the innovative character of our machinery and made us what we are today.